3 Things Procurement Gets Wrong About CapEx (and How You Can Get It Right)

This blog was refreshed on October 16, 2023.

When it comes to procurement, CapEx (Capital Expenditure) is often overshadowed by OpEx (Operational Expenditure). However, as industries undergo transformative changes, CapEx procurement is gaining prominence. Transitioning from the familiarity of OpEx to the intricacies of CapEx can be a complex endeavor.

Most procurement teams focus on OpEx procurement rather than CapEx. OpEx includes categories such as raw materials, packaging, and office supplies. The super category covers anything a sourcing team would source daily, and thus has repeatable, scalable, and efficient processes associated with it.

CapEx, on the other hand, covers items bought once, or seldomly, including significant capital expenditures such as custom equipment for a production facility or the building materials for an entire high rise. CapEx-focused procurement teams are typically found in the construction industry or industries with large amounts of specialized manufacturing, like the automotive industry.

With manufacturing processes changing, CapEx procurement is becoming more common in the manufacturing sector. The growing popularity of electric vehicles results in new plants being built and existing assembly plants having to adopt entirely new production processes, which is just one example. The energy sector is also poised for CapEx growth.

The sudden demand for CapEx specialized teams creates unique challenges. OpEx teams are adapting to fill the need, but ultimately CapEx and OpEx procurement each require a very different approach. There is ample opportunity for operationally-focused procurement professionals to get a CapEx project wrong.

Before looking at three things that frequently trip up procurement teams, let’s take a quick look at the primary differences between CapEx and OpEx procurement.

CapEx Vs. OpEx

CapEx Procurement

-

-

- Purchases are often one-offs

- Purchases are often large and are intended to last a long time

- Purchases are likely to be custom made

- Examples include new manufacturing plants, cranes, or production equipment

-

OpEx Procurement

-

-

- Daily purchases a company makes

- Covers everything from raw materials to packaging and even office materials

- Purchases are repeated

- Creating a scalable procurement process is very important

-

Three Things Procurement Professionals Get Wrong About CapEx

CapEx Procurement is Singular

OpEx procurement uses processes that are based on repeatability. That does not apply well to capital expenditure. Instead, CapEx is a one-time purchase, and in some cases (such as a building), it’s something unique. That means the procurement team working on a CapEx project needs to focus on specifics: ensuring delivery satisfies requirements, the budget, and the delivery timeline.

CapEx Procurement Includes Change Orders

Change Orders can be a big part of Capital Expenditures. Project managers on both sides often oversee a large project and change orders are standard. That might be the bill of materials associated with the project or even its scope. It’s critical to track the costs associated with change orders throughout a CapEx project; otherwise, it’s easy to lose track of financial outcomes.

CapEx Procurement has Customized Specs

With OpEx procurement, sourcing teams buy products or materials “off the shelf.” They usually have a SKU. There is a great deal of predictability because sourcing teams deal with standardized products or materials, known suppliers, and have access to historical pricing. It’s relatively easy for procurement to find suppliers that meet the requirements.

CapEx procurement is very different in this respect. The sourcing team is purchasing a unique product or deliverable. Specifications aren’t off-the-shelf; they may be highly bespoke.

Muddying the waters is the reality that some capital expenditure projects may have OpEx-applicable components. For example, a new building might have recurring expenditures such as pipes or wires. The sourcing team might want visibility into these costs instead of having them rolled up into a blanket invoice for the project.

Pro Tips to Getting CapEx Right

There are many opportunities for a capital expenditure project to go sideways if the procurement team takes the wrong approach. So how do sourcing professionals who are more accustomed to dealing with operational expenses ensure they succeed with a CapEx project? Here are a few pro tips to getting CapEx procurement right.

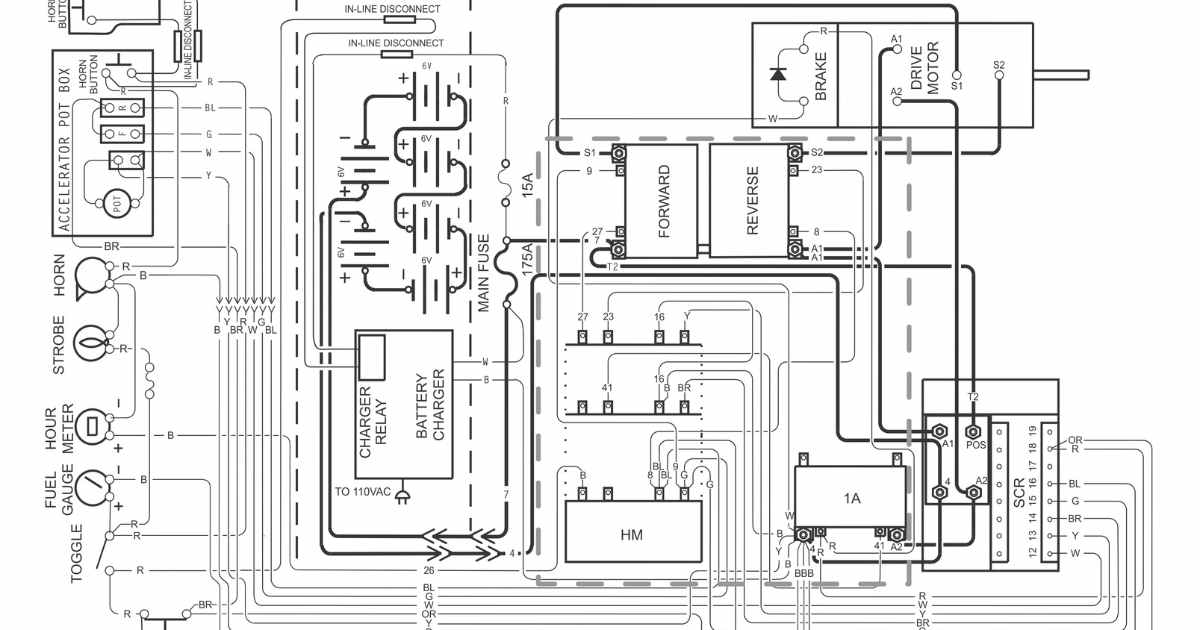

One “hack” that can make a massive difference in the success of a CapEx project is the use of multimedia. If you have blueprints, drawings, schematics, or videos that will help suppliers to fully understand what you’re looking for, include them as part of the bid packet. Doing so helps to communicate the requirements, helps potential bidders ask better questions, and saves you from having to contact each supplier individually to explain details.

Suppliers who deal with CapEx projects are often highly specialized and experts. So, leave room on your RFP or RFQ for suggestions if they have a different idea about approaching the project. They may propose a different solution that could have a significant impact on the success of the project.

Make sure to ask suppliers for a detailed bill of materials complete with the unit of measure. Otherwise, you’ll have difficulty analyzing the costs to reduce the project expense by targeting expensive components. Having the transparency of units of measurement in a detailed bill of materials also makes it easier to compare supplier quotes.

Finally, use Predictive Insights to understand how much supplier change requests will be adding to the cost of the project’s cost. For example, the supplier may come back mid-project to say they need to purchase additional wiring. With predictive quoting, you’ll have insight into how much that change request is going to cost—a valuable tool in approving change requests using empirical data instead of a subjective decision.

The Biggest Step for Procurement Teams to Optimize Their OpEx and CapEx Capabilities

We’ve explored the fundamental differences between CapEx and OpEx procurement and the ways even seasoned procurement professionals can get tripped up with CapEx. They often underestimate three critical factors in CapEx projects: the necessity for a focused and precise approach, the inclusion of change orders, and the customization of specifications.

Now it’s time to take the step that will have the biggest impact on how your procurement team deals with CapEx, OpEx, and the potential for overlap between the two. By bridging the gap between OpEx and CapEx with Arkestro, procurement teams can optimize their capabilities and navigate complex projects with confidence.