Untangling Manufacturing Procurement with Data Analytics in the “Next Normal”

Procurement can be a cumbersome process for contract manufacturing operations, which must procure on behalf of their customers to meet rapidly changing production requirements. Determining the total delivered costs for any given Bill of Materials can often be very complex, according to David Schultz, VP and Global Supply Chain Executive of Westfall. In the podcast “Using Data to Untangle the Sticky Problems of Manufacturing Procurement — with David Schultz of Westfall,” Schultz notes that persistent shortages in the plastics and resins industry have resulted in frequent force majeure declarations, and he believes that the current situation may be best described as the “next normal.”

Three key insights from the podcast with David

Data-Driven Metrics That Matter

Speed to Margin

The time it takes to arrive at a final price during a negotiation.

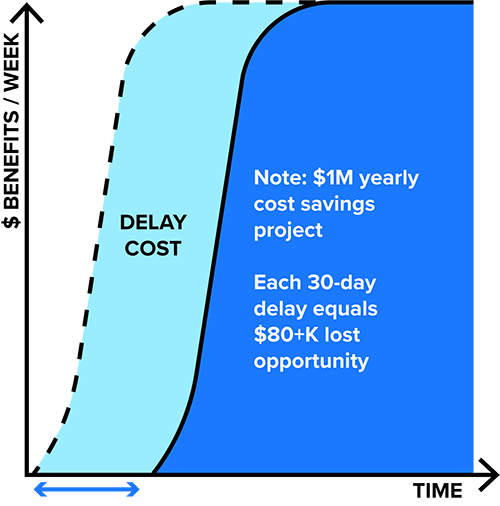

Cost of Delay

Transparency in Data Confidence

“Systems like Arkestro are easy to use and you’re not downloading all kinds of data. People understand how to use it from the start - you can continuously pulse the market to ensure you are staying competitive.”

— DAVID SCHULTZ

VP AND GLOBAL SUPPLY CHAIN EXECUTIVE OF WESTFALL

Manufacturers Can Leverage Predictive Procurement to:

Make every decision their best decision

Gain speed with confidence

Scale their

influence

For David’s team, the ability to offer suppliers more complete and timely feedback is certainly an asset in building trust through transparency and using data to run more procurement cycles faster.