Procurement in the Chemical Industry: The Future Is Predictive

Few industries are as massive and complex as the nearly $5 trillion chemical manufacturing industry. Globally, it plays a vital role in the economy, employing around 20 million people.

Chemical manufacturers turn an array of raw materials—gas, minerals, metals, and more—into countless products used in everyday life. Consumers end up directly using some of these products, but many of the chemicals produced become critical components used by various other industries. Food production, automobile manufacturing, farming, and pharmaceuticals are just some areas where chemicals play a crucial role.

Predictive procurement is the key to securing raw materials at the right price and time. We explore how predictive procurement in chemical manufacturing will be strategic as we move into 2023.

Challenges and Opportunities for Procurement in Chemical Manufacturing

Procurement plays a critical role in chemical manufacturing, but it’s also a challenging one. Some raw materials are in short supply, and others are dangerous to extract, transport, and store.

Since raw materials are expensive—accounting for anywhere from 50% to 70% of sales revenue for chemical companies—procurement is in the spotlight. Reducing costs in the industry by even a fraction has a huge impact on profitability.

But beyond impacting cost, factors like economic uncertainty, supply chain disruption, and changing consumer preferences are transforming procurement in the industry.

Deloitte released a report on the 2023 chemical industry outlook. Their analysis highlights how the industry will need to evolve to overcome the disruption of 2022:

“Chemicals and materials are ubiquitous in a modern-day lifestyle, and for chemical producers to operate in an evolving global geopolitical landscape, there will be a strong need to make fundamental changes, either proactively or reactively. In the coming year, chemical companies will likely have to plan for challenges—from global inflation to oil price volatility. This combination could make 2023 an important year for a strategic shift.”

Preparing for challenges is critical. So how does the industry prepare and build a bright future? The Deloitte report points out that supply chain will need to consider different strategies to meet the changes coming. This means procurement in the chemical industry will need to be innovative.

Predictive Procurement: A Strategic Shift for Chemical Manufacturing

With predictive procurement, teams can predict outcomes with confidence. They can be proactive in their supplier management instead of reactive.

The behavioral uncertainty of a supplier can be a massive challenge for procurement teams. Through behavioral modeling, predictive procurement gives teams deep insights to improve outcomes. Modeling supplier behavior based on past interactions to help predict possible future outcomes can help teams recommend the best price to a supplier.

Predictive procurement platforms like Arkestro leverage behavior science, game theory, and machine learning for predictive pricing and the generation of real-time recommendations. No advanced knowledge is needed to quickly and easily generate reports, predictive pricing, and analytics required to support data-driven decision-making.

The result: faster and more efficient procurement cycles.

Predictive Pricing in Action

Any chemical manufacturing company is going to amass vast amounts of data concerning procurement. But that data is of little use if people can’t easily analyze it. Traditional tools make it challenging to aggregate and pull meaningful information from complex data.

And having all this data means little if you can’t gain insight from it. Worse, you could make critical procurement decisions based on an incomplete and inaccurate analysis.

A few years ago, a large chemical producer met with Arkestro. At the time, overall complexity was an issue. They had a lot still built in Excel, so it was challenging to get all their information together. Their process was also cumbersome and time intense, an area where Arkestro’s embedded platform was able to help.

But driving prices was even more important than managing this complexity. A successful outcome is when the price is where the client wants it—or even better, below that. This made Arkestro’s price recommendation appealing from the beginning, and ultimately a game changer.

For instance, whoever goes first in a negotiation can make a huge difference. Research on the anchoring effect suggests that the party making the first offer can gain a powerful advantage. However, if you choose the wrong anchor, it could work against you.

This is why Arkestro’s price recommendation is so valuable: instant recommendations use internal and external data and learn from your best purchasing decisions. As a result, you get the right price quickly.

Hear more about how Arkestro has helped clients during the Optimal ’22 predictive procurement in action case studies.

How Using Human Behavior Science and Game Theory Benefits Procurement

Arkestro users have the advantage of a predictive negotiation process based on behavioral modeling and game theory.

A vast range of variables is considered, including supplier reputation, historical raw material prices, competition, and product budget. In a short time, Arkestro’s embedded platform performs a comprehensive analysis for quick award decisions and can then recommend a price.

Not only does this cut costs, but the speed of Arkestro’s embedded platform also offers a significant competitive advantage by beating others to the market.

In addition to the advanced abilities of predictive procurement, Arkestro delivers a wide range of critical features:

- Real-time collaboration

- Advanced supplier management and evaluation tools

- Evident transparency throughout the procurement process

- Easy integration with other commonly used software

Arkestro: Elevating Chemical Manufacturing Procurement

Procurement technology is changing the decision-making landscape of chemical producers.

Predictive Procurement Orchestration represents the leading edge of the new wave of digital procurement. It influences all addressable spend and leverages a unique approach to predictive pricing.

Arkestro pulls in your company’s internal data, including purchase orders, supplier master, category data, and contract data. It also pulls external data, including supplier information, ESG, and diversity datasets, and then cleanses and validates the data.

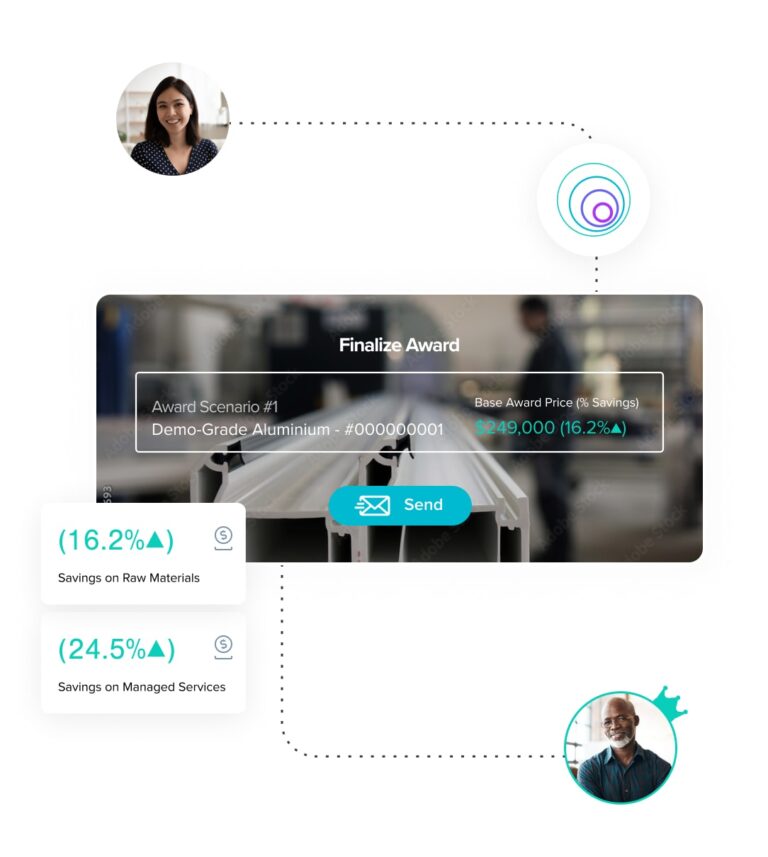

Arkestro does this using three broad motions: Simulate, Send, Select.

- Simulate: Arkestro simulates a sourcing or purchasing event to predict prices and terms.

- Send: Akrestro emails a recommended offer to the supplier(s) for review, revision, and acceptance.

- Select: Arkestro recommends holistic awards and approvals using many possible scenarios. Awards reflect an organization’s intent and are based on KPIs and the unique purchasing and pricing history of the line items involved. Arkestro’s award recommendations can be tweaked or manually overridden, so the procurement team is always in the driver’s seat.

Procurement teams end up with tangible business results:

- Quicker and more impactful supplier engagement

- Greater amount of spend actively influenced using predictive models

- Increased cost savings and/or cost avoidance across more spend

- Better and faster quality decision-making across the organization

- Incorporation of supplier ESG, diversity, and risk metrics into spend decisions

To learn more about how Arkestro can elevate chemical manufacturing procurement to a new level, see Arkestro’s predictive purchasing in action.